| Availability: | |

|---|---|

| Quantity: | |

diamond

opticwave

Advanced Consumables

Below is the application of our Lapping Film in Fiber Optic, such as Ceramic Connectors, MPO/MTP Connectors, POF Connectors as well as fiber arrays.

Fiber Optic Connector Polishing

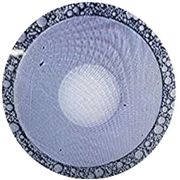

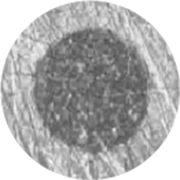

Ceramic Ferrule Connector Surface after Polishing

D30 (Diamond 30µm)

D9 (Diamond 9µm)

D1 (Diamond 1µm)

Final Polishing Film

MPO/MTP Connector Surface after Polishing

SC16

SC3

Fiber-up Slurry

Final Polishing Slurry

| Step | Polishing Film | Process | Lifetime | ||||

| Micron | Mineral | Product | Pad | Liquid | Time | ||

| Remove Epoxy | 30µm | Diamond | D30 | 80 D | DI water | 30-35s | >30 plates |

| Rough Polishing | 9µm | Diamond | D9 | 80 D | DI water | 30-35s | >30 plates |

| Fine Polishing | 1µm | Diamond | D1 | 80 D | DI water | 35-40s | >30 plates |

| Final Polishing | 0.02µm | SiO2 | SO/ADS | 70 D | DI water | 30-40s | >8 plates |

What’s more, the life time of Grish Diamond Laping Film is over 30 plates, while ADS is over 8 plates, which will help you save a great amount of cost.

During the process please use our suggested polish pads, do the cleaning accordingly and set the working time correctly, so you will get the ideal finish for your Ceramic Connectors.

| Film Model | Polishing Time/S | Pressure/Pound | Rpm/min | Polishing Pad | Polishing Agent | Lifetime |

| SC16 | 50S | 2 | 110 | Glass Pad | DI Water | ≤2 plates |

| SC3 | 130S | 2 | 130 | Glass Pad | DI Water | ≤2 plates |

| PUMD | 140S | 5 | 160 | Glass Pad | AO-1-50B | ≥40 plates |

| PUMZ | 40S | 5 | 160 | Glass Pad | CO-1-30B | ≥40 plates |

During the process please use our suggested glass pads, do the cleaning with polishing agent accordingly and set the working time, pressure & RPM correctly, so you will get the desirable finish for your MPO/MTP Connector.

There are 5 steps for your MPO/MTP Connector Polishing , firstly use our SC16 for epoxy remove, then SC9 for rough polishing, after that using SC3 for fine grinding, fourthly choose PUMD for further polish, lastly finish final polishing with PUMZ.

| Mesh | 180 | 240 | 360 | 400 | 600 | 1000 | 1200 | 2000 | 2500 | 4000 | 6000 | 8000 | 10000 |

| Particle Size(µm) | 80 | 60 | 45 | 40 | 30 | 16 | 15 | 9 | 6 | 3 | 2 | 1 | 0.5 |

| Standard Size | Round: Φ70mm, Φ110mm (4.3inch), Φ127mm (5inch), Φ203mm(8inch) | ||||||||||||

| Rectangle: 114mm*114mm, 152mm*152mm(6inch), 228mm*280mm (9*11inch) | |||||||||||||

Advanced Consumables

Below is the application of our Lapping Film in Fiber Optic, such as Ceramic Connectors, MPO/MTP Connectors, POF Connectors as well as fiber arrays.

Fiber Optic Connector Polishing

Ceramic Ferrule Connector Surface after Polishing

D30 (Diamond 30µm)

D9 (Diamond 9µm)

D1 (Diamond 1µm)

Final Polishing Film

MPO/MTP Connector Surface after Polishing

SC16

SC3

Fiber-up Slurry

Final Polishing Slurry

| Step | Polishing Film | Process | Lifetime | ||||

| Micron | Mineral | Product | Pad | Liquid | Time | ||

| Remove Epoxy | 30µm | Diamond | D30 | 80 D | DI water | 30-35s | >30 plates |

| Rough Polishing | 9µm | Diamond | D9 | 80 D | DI water | 30-35s | >30 plates |

| Fine Polishing | 1µm | Diamond | D1 | 80 D | DI water | 35-40s | >30 plates |

| Final Polishing | 0.02µm | SiO2 | SO/ADS | 70 D | DI water | 30-40s | >8 plates |

What’s more, the life time of Grish Diamond Laping Film is over 30 plates, while ADS is over 8 plates, which will help you save a great amount of cost.

During the process please use our suggested polish pads, do the cleaning accordingly and set the working time correctly, so you will get the ideal finish for your Ceramic Connectors.

| Film Model | Polishing Time/S | Pressure/Pound | Rpm/min | Polishing Pad | Polishing Agent | Lifetime |

| SC16 | 50S | 2 | 110 | Glass Pad | DI Water | ≤2 plates |

| SC3 | 130S | 2 | 130 | Glass Pad | DI Water | ≤2 plates |

| PUMD | 140S | 5 | 160 | Glass Pad | AO-1-50B | ≥40 plates |

| PUMZ | 40S | 5 | 160 | Glass Pad | CO-1-30B | ≥40 plates |

During the process please use our suggested glass pads, do the cleaning with polishing agent accordingly and set the working time, pressure & RPM correctly, so you will get the desirable finish for your MPO/MTP Connector.

There are 5 steps for your MPO/MTP Connector Polishing , firstly use our SC16 for epoxy remove, then SC9 for rough polishing, after that using SC3 for fine grinding, fourthly choose PUMD for further polish, lastly finish final polishing with PUMZ.

| Mesh | 180 | 240 | 360 | 400 | 600 | 1000 | 1200 | 2000 | 2500 | 4000 | 6000 | 8000 | 10000 |

| Particle Size(µm) | 80 | 60 | 45 | 40 | 30 | 16 | 15 | 9 | 6 | 3 | 2 | 1 | 0.5 |

| Standard Size | Round: Φ70mm, Φ110mm (4.3inch), Φ127mm (5inch), Φ203mm(8inch) | ||||||||||||

| Rectangle: 114mm*114mm, 152mm*152mm(6inch), 228mm*280mm (9*11inch) | |||||||||||||